Tasker Millward School

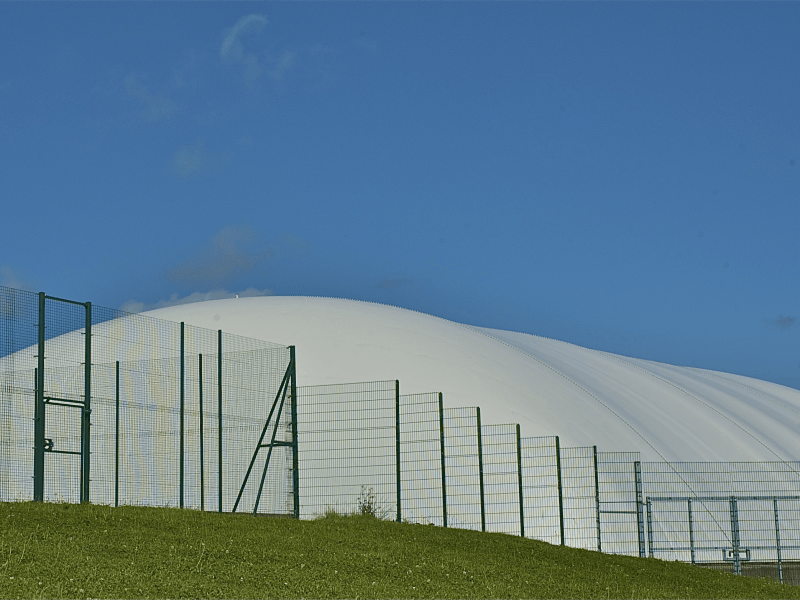

The original Dutch made air dome collapsed due to a combination of vandalism and lack of maintenance and was rendered irrepairable. Up to that point it had been a key facility for the school, so the quick manufacture and installation of a new dome was imperative to the day-to-day running of the school.

As no drawings existed of the critical details, J & J Carter undertook a site survey, measured and drew up everything from scratch including updating some of the details.

As a specialist contractor, J & J Carter were able to design, manufacture and install a sustainable replacement membrane within a short time frame. Starting with the site survey, J & J Carter took full design responsibility. Due to the sheer size of the dome, it was fabricated off-site in manageable sections with each section site jointed to its neighbouring section with a mechanical joint. The total weight of the membrane was 6.5 tonnes, which had to be inflated to the required pre-stress and form.

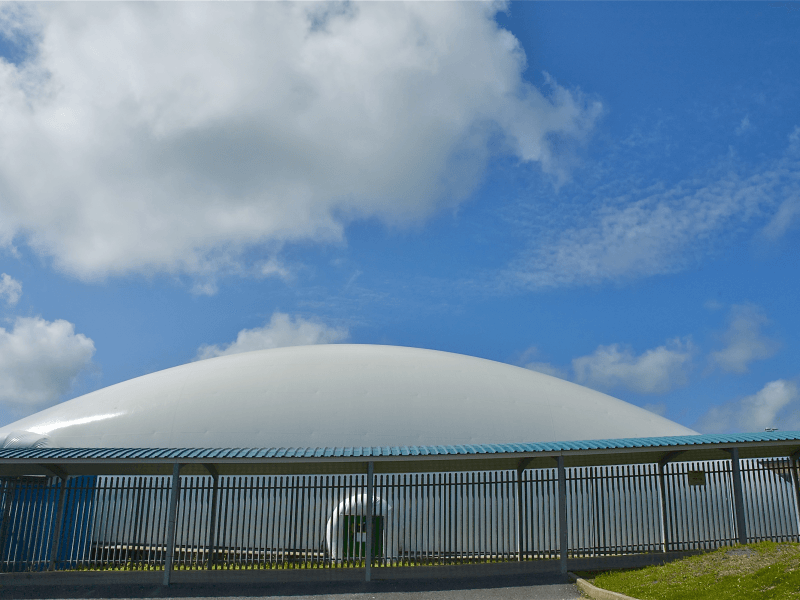

The outer dome fabric is a Type 3 PVC from Mehler Texnologies. The PVDF top lacquer gives excellent protection and makes for easier cleaning and maintenance. The inner lining is a Type 1 650gsm PVC from Mehler. The lower 3m is in a constrasting blue whilst the remainder is white which helps to reflect the light within.