Design & Engineering

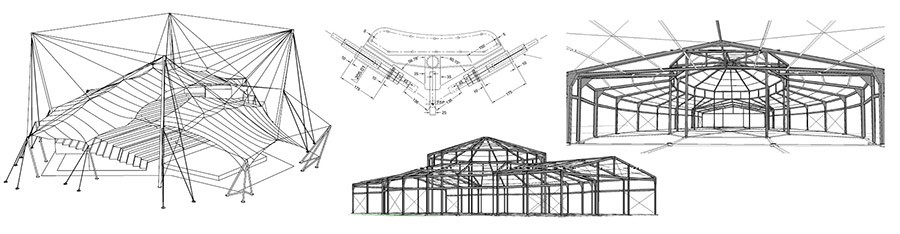

Tensile structures permit the design of exciting forms that would be almost impossible with traditional building methods.

At J&J Carter, we don't just build tensile structures; we craft architectural masterpieces. Our team of expert engineers and designers combines cutting-edge technology with a passion for innovation to create breathtaking and functional spaces that push the boundaries of traditional construction.

The structures are all prefabricated to engineered drawings and calculations.

Preliminary Design and Modelling

The initial phase of the design process involves conceptualising the structure and creating preliminary models that showcase the key design elements. Our team uses advanced software tools to visualise and simulate the form and behaviour of the tensile fabric structure under various environmental conditions. This stage helps identify potential challenges early on and ensures that the design is aligned with both the client’s vision and the project’s functional requirements.

Membrane Form Finding and Analysis

The form-finding process is a critical aspect of tensile fabric design, as it determines the optimal shape of the membrane to achieve both aesthetic appeal and structural efficiency. Through a combination of computational techniques and physical simulations, we analyse the way the membrane responds to applied loads and environmental forces. This analysis ensures that the final shape maximises both strength and aesthetic quality while maintaining structural integrity.

Supporting Structure Design and Analysis

The supporting framework of a tensile structure plays a pivotal role in ensuring its stability and safety. Our engineers design and analyse the supporting structure, including cables, masts, and other elements, to ensure they work in harmony with the membrane. We use sophisticated modelling tools to simulate the entire system's behaviour, taking into account factors like wind, snow, and seismic loads, to ensure optimal performance.

Detail Design and Engineering

In the detailed design phase, we refine the structure’s components to ensure that every element is practical, functional, and safe. Our team prepares detailed engineering drawings, specifying materials, dimensions, and construction techniques. We focus on precision and clarity, ensuring that all aspects of the design comply with industry standards and regulatory requirements.

Material Testing

To ensure the durability and performance of the materials used, we conduct uni-axial material testing, which involves applying force in a single direction. This testing up to 25 kN helps determine the strength and flexibility of the membrane materials, ensuring they can withstand the expected loads without compromising structural integrity. These results inform our material selection and design decisions, providing a solid foundation for the project.

In addition to uni-axial testing, bi-axial testing is performed to simulate the material’s behaviour when subjected to forces in two directions. This testing, conducted up to 20 kN, is especially important for fabrics that will experience multi-directional forces, ensuring they maintain their shape and strength under complex loading conditions.

- Uni-Axial Testing (up to 25 kN): Determines the strength and flexibility of the membrane under tension in a single direction.

- Bi-Axial Testing (up to 20 kN): Simulates real-world conditions by applying forces in two directions, ensuring the membrane's stability under complex loading scenarios.

Steelwork Fabrication Drawings

Our engineering team produces detailed fabrication drawings for the steelwork components of the structure. These drawings provide precise specifications for the fabrication and assembly of the supporting framework, ensuring that the steel elements meet the design criteria and can be manufactured with the necessary accuracy and quality.

Membrane Cutting Patterns

To ensure the membrane is cut with precision and efficiency, we create detailed cutting patterns based on the shape and dimensions of the final structure. These patterns are used to guide the fabrication process, ensuring that the membrane fits perfectly and can be installed smoothly. By using advanced cutting technology, we minimise waste and maximise material use, contributing to a more sustainable process.

Our engineers undertake a total design and engineering solution including all drawings to satisfy both Architectural and Building Regulations approval whilst creating stunning tensile architecture.

Serving Diverse Sectors

We have extensive experience designing and engineering tensile structures for a wide range of applications:

- Education: Creating inspiring and functional learning spaces.

- Healthcare: Designing healing environments with natural light and open spaces.

- Transport: Providing weather protection and creating iconic landmarks for transportation hubs.

- Sports & Leisure: Building dynamic and versatile venues for sporting events and recreational activities.

- Commercial & Retail: Creating eye-catching and welcoming spaces for businesses.

From concept to completion, quality is at the heart of everything we do. We adhere to the highest industry standards and employ rigorous quality control processes to ensure that every structure we create is built to last. Ready to explore the possibilities of tensile architecture? Contact us today for a free consultation. Let's collaborate to create a space that is as functional as it is breathtaking.