Wise Handing – Siemens Train Lift Cover

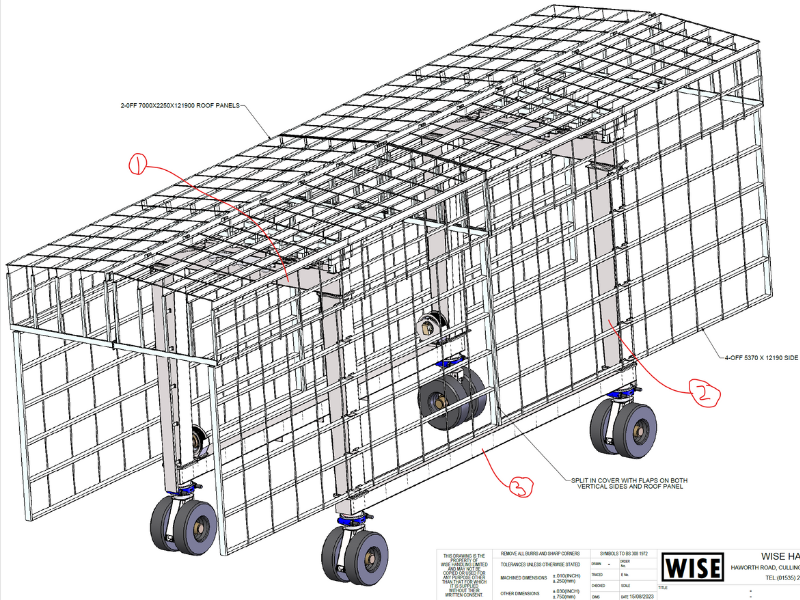

Wise Handling, based in Bradford, West Yorkshire, required a large, custom machine cover for a straddle carrier used by their client, Siemens. This carrier, designed to lift 60 tonne trains for maintenance and repair, needed a durable cover to protect ongoing work from the elements.

Key Challenge

The primary challenge involved the development of a single-piece cover that was sufficiently large to provide comprehensive protection for the entire structure. This necessitated careful consideration of both the dimensions and the material properties to ensure that the cover could withstand various environmental conditions while maintaining its integrity over time.

In addition to size, it was essential to focus on durability; the cover needed to be resistant to wear and tear, as well as potential impacts, to safeguard against any operational disruptions. The installation process also had to be straightforward, allowing for efficient setup without compromising the structural integrity or protective capabilities of the cover.

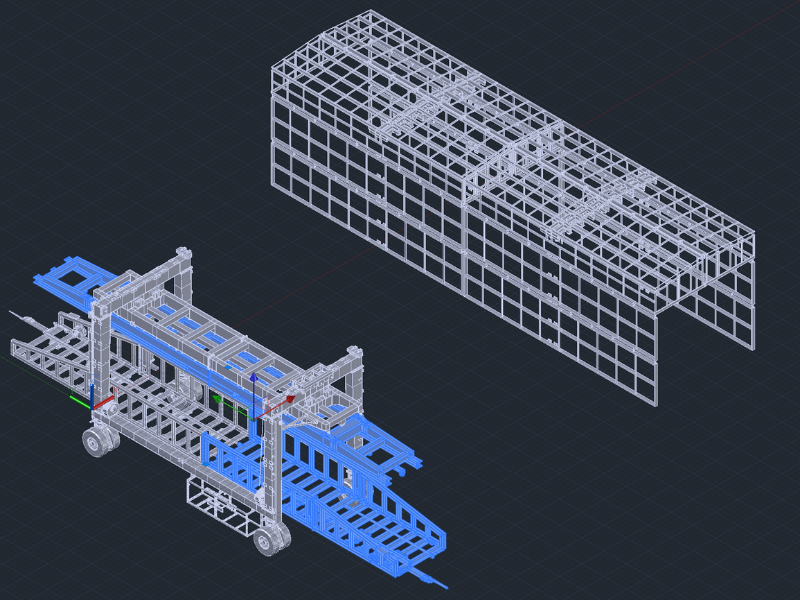

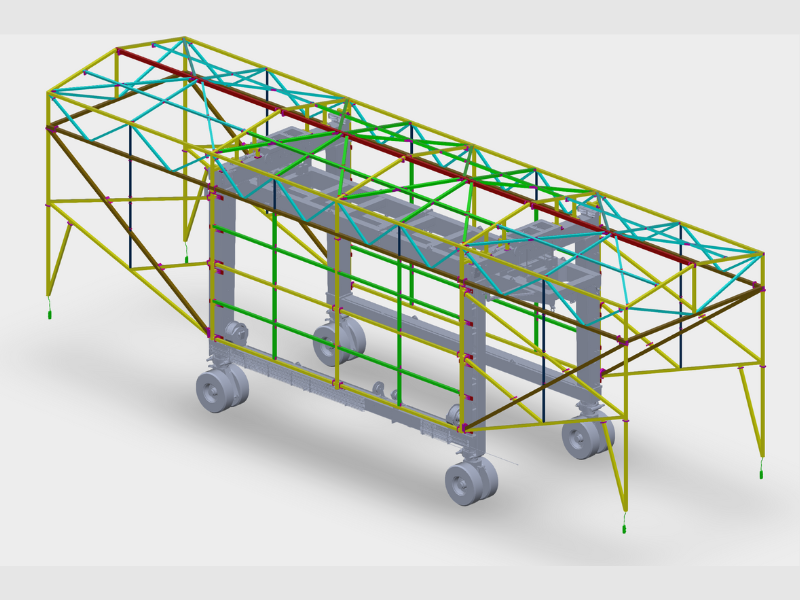

Given the considerable scale and intricate nature of the project, a robust support frame was crucial. This frame would not only provide the necessary structural support but would also aid in the precise fitting of the cover onto the designated area. Attention to detail in the craftsmanship was paramount to ensure that the cover met the specific operational needs outlined by Siemens, allowing for seamless integration into their existing systems while maintaining accessibility for any required maintenance or inspections.

Solution

Artura took the lead in both the design and engineering aspects of the project, creating a meticulously crafted steel supporting frame that was expertly manufactured by SH Structures located in Leeds. In parallel, J & J Carter undertook the task of producing an impressive PVC cover designed to shield and protect the structure. They selected a high-quality 900gsm Panama PVC material in a vibrant orange color, ensuring not only durability but also high visibility.

Weighing over 700 kilos, this single-piece cover was designed to meet stringent functionality requirements. It offered Siemens a robust solution that effectively withstands various weather conditions, ensuring long-term performance and protection for the underlying structure. The careful selection of materials and the engineering precision involved highlight the commitment to quality and functionality in this project.

Outcome

This unique project allowed J & J Carter to showcase expertise in creating bespoke PVC covers. Both Wise Handling and Siemens were thrilled with the result, which met all specifications and offered excellent protection for train maintenance operations.