FARM250 Anaerobic Digester FAQs

03 Apr 23The FARM250 is the next generation of anaerobic digesters, designed for smaller, family-sized farms, and enables sustainable farming whilst reducing costs and minimising a negative environmental impact. J & J Carter has collaborated with Bioplex to develop a comprehensive anaerobic digester for pollution control, material recycling, and energy recovery. Using both aerobic and anaerobic digestion procedures, it treats and transforms organic waste into valuable end-products and energy. Below we answer the most common questions asked about the Farm250 Anaerobic Digester.

What Are the Benefits of the FARM250 Anaerobic Digester?

There are many benefits to installing an anaerobic digestor for smaller-scale farms and facilities, including, renewable energy production to become carbon neutral, reduction of greenhouse gas emissions, waste reduction, nutrient recovery, cost savings and job creation.

Anaerobic digesters produce biogas, a renewable energy source that can be used to generate electricity and heat. Biogas can also be purified into biomethane and used as a vehicle fuel or injected into the natural gas grid. Discover more on how anaerobic digester systems work.

The FARM250 Anaerobic Digester reduces greenhouse gas emissions by capturing methane during the decomposition of organic waste, that would otherwise be released into the atmosphere. The end-product produced by anaerobic digestion is a nutrient-rich fertiliser that can be used to improve soil health and crop productivity.

Not only does anaerobic digestion save money, but it also requires trained personnel to run and maintain, creating job possibilities in rural areas where it is frequently found.

Will the FARM250 Anaerobic Digester Help towards a Circular Economy?

Anaerobic Digestion turns waste materials into renewable energy and nutrient-rich fertiliser and is seen as a crucial technology to increase the sustainability of the industry, reduce carbon emissions and is seen as vital in helping the region move to a low-carbon, circular economy.

Will the System Run on Slurry Alone?

In simple terms, yes! As a component of a slurry management plan, the FARM250 Anaerobic Digester is effective at increasing the amount of slurry you can store and the amount of methane you can collect from the slurry's breakdown process. This is a desirable choice if the NVZ (nitrogen vulnerable zones) regulations require you to increase your slurry storage.

Is the FARM250 Anaerobic Digester Safe?

At J & J Carter we are dedicated to ensuring we meet the requirements of guidelines and changes in regulations that concern the structural design and engineering of temporary and permanent structures. This helps to ensure the safety of employees, the public and others who could be affected by such structures.

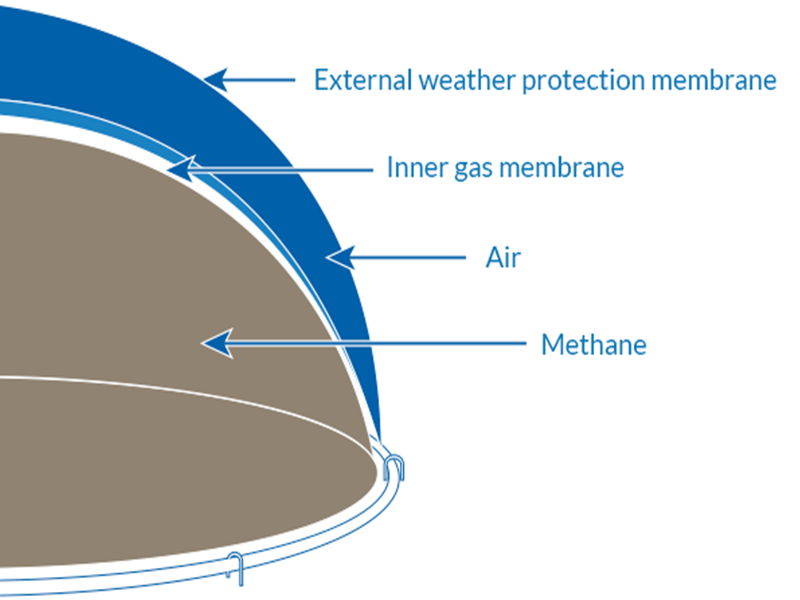

The Farm250 Anaerobic Digester has been designed to meet local and national codes for safety. However, they do produce methane and hydrogen sulphide and these gases both burn easily and are harmful to inhale, so it is essential to use proper gas-handling precautions. It is also important for plant operators to be well-trained and follow established operational procedures.

Is the Farm250 Anaerobic Digester Right for Me?

The Farm250 Anaerobic Digester is suitable under many circumstances, including treating waste, reducing odours, providing a revenue source and improving public image. While simple in concept, there are many sizes, styles and applications of digesters. Projects require detailed technical and financial planning to be successful.

Here at J & J Carter, we pride ourselves on the high-quality service we offer our clients. Each system is designed, manufactured, and installed to your bespoke needs. For more information about the Farm250 Anaerobic Digester, contact our knowledgeable team today who will be happy to answer any further questions you may have.