Repair Keder & Keder Rails

To replace a worn keder using our repair keder system please follow the procedure in the PDF download. Should a Fabricator prefer to sew on top of the old keder, it is advisable to High-Frequency weld over the sewn area after sewing. This process will allow the PVC from the inside of the repair keder to flow and fill any holes created during the sewing process. If sewing, we normally recommend using a Twin Needle machine; however, this is the choice of the fabricator or repair shop technician. All of our repair keders are available in our standard coil lengths of 150 metres. For users requiring shorter lengths, these can be procured through our distributors.

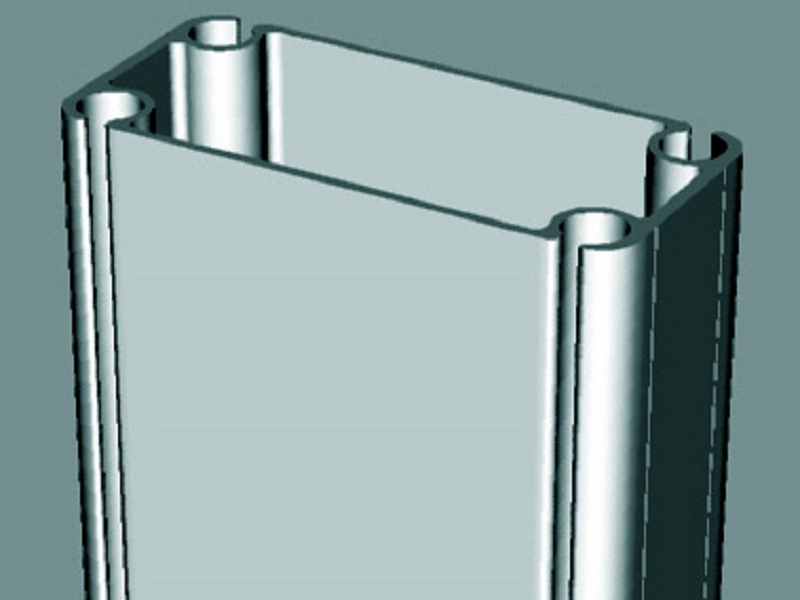

Keder Rails

We stock mill finish aluminium Keder Rails which can be fitted to your structures. We also hold stock of our own structure extrusions which can be used as structural members.