FIXED / SLAB MOUNTED ANAEROBIC DIGESTORS

J & J Carter, in partnership with Bioplex, have created a comprehensive anaerobic digester for biogas production. Our FARM range of digesters are larger systems; enabling a variety of solid wastes such as manures, silage, crops and vegetation to be digested. This enhanced model conforms to ABPR Cat 3 and enables the digestion of large volumes of food and/or animal by-product waste.

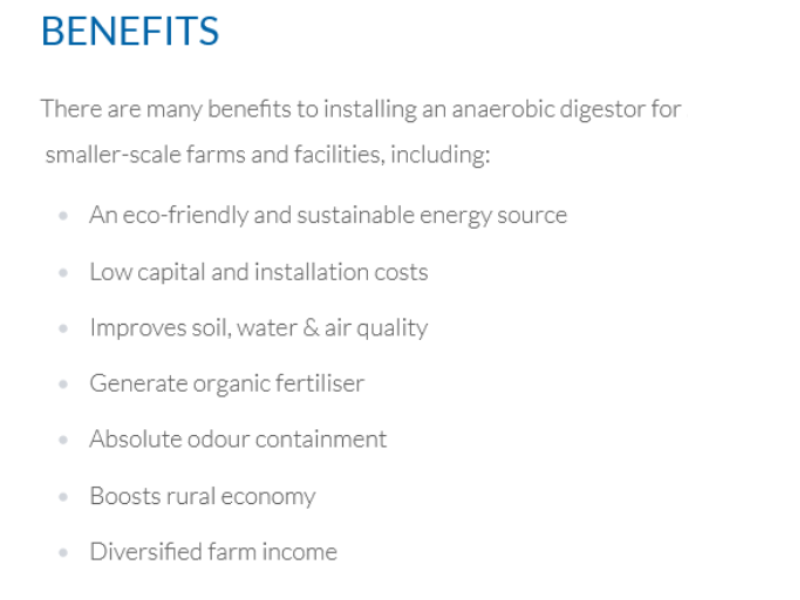

Our anaerobic digesters enable sustainable farming, while reducing costs and minimising environmental impact. Anaerobic digestion is complementary to other renewable energy sources, such as wind, solar and micro-hydro. With a new generation of digesters, the farm can meet all its energy needs, with the surplus energy made available for the local community.

The FARM ANAEROBIC Digester System Models:

- FARM250 – Mixed Waste Digester, such as FYM and vegetation with daily inputs of 4 to 5 tonnes.

- FARM250/F – Large Scale ABPR Cat 3 Digester for food and animal by-product wastes with daily inputs of 4 to 10 tonnes (depending upon DM rate)

- FARM500 – Larger version of the FARM250 with daily inputs of 8 to 10 tonnes of mixed waste.

| Feedstock (example) | Capacity Tonnes per day | Estimated BioGas Yield m³/hr | Estimated Electricity kW |

Potential Heat kW |

|

FARM250 |

Farm yard manures Slurry |

4 – 5 manure 15 - 20 slurry |

12 – 15 | 20 – 30* | 35 - 60* |

FOOD250 |

Organic, Food, Animal by-product wastes | 4 – 10 | 10 – 20 | 15 – 40* | 25 - 100* |

FARM500 |

Farm yard manures Slurry |

8 - 10 manure 30 - 40 slurry |

25 - 30 | 45 - 60* | 75 - 120* |

*The above calculations are for illustration only. Biogas yield and therefore electricity output is variable due to factors such as % dry matter, volatile solids, age of feedstock, inhibitors and % methane in the biogas.

What is anaerobic digestion?

Anaerobic digestion is a series of biological processes in which microorganisms break down biodegradable materials in the absence of oxygen. One of the end products is biogas, which is combusted to generate electricity and heat, or can be processed into renewable natural gas and transportation fuels. Anaerobic digestion converts livestock manure, municipal wastewater solids, food waste, and other organic waste streams into biogas - 24 hours a day, 7 days a week. Separated digested solids can be composted, utilised for dairy bedding, directly applied to cropland or converted to other products. Nutrients in the liquid stream are used in agriculture as fertiliser.

Is this system right for me?

By gathering a few simple details, our team can guide you through a completely FREE, no obligation enquiry process to evaluate your establishment and the feedstock available. Once we are confident that the required outputs can be achieved our team will begin the next step of the evaluation process, which includes sample collection and detailed feedstock analysis.

Visit one of our Fixed anaerobic digester systems

Once the analysis phase is complete, we would be delighted to arrange a visit to this fully operational site, which has been successfully generating biogas and fertiliser for over seven years:

- Stockbridge, Hampshire – FARM250 treating FYM, Slurry and Vegetation.

Maintenance and Cleaning of Anaerobic Digestion Systems

The build-up of debris and grit can negatively impact the operation of digesters, reducing biogas yield. Once this build-up occurs, it is imperative to perform a thorough clean of the digester tank. It’s essential to contract trained and experienced personnel who can quickly and safely remove all organic and inorganic materials that interfere with the overall operation.

No matter how advanced your digestor is, it will eventually need to be cleaned. We recommend a thorough cleaning of your digestor every 3 to 6 years. During the cleaning process, it is also important to inspect the digester system and take steps to ensure everything is working properly.

Environmental & Agricultural Solutions

Unlock the Power of Anaerobic Digestion

Invest in a sustainable future and see long-term savings with our Hybrid Anaerobic Digester range. Designed to maximise energy efficiency and minimise waste disposal costs. Get a free, no-obligation quote for your chosen AD System and take the first step towards generating sustainable energy.

Request a Quote