PG Range - Trailer Mounted Relocatable Systems

The PG (or Portagester) is a trailer or skid mounted mobile digestion unit. This can treat a variety of wastes by pasteurising, hydrolysis and separation into solids and liquor. The contents remain in an enclosed vessel, from loading, treatment, transport and tipping where it is to be used.

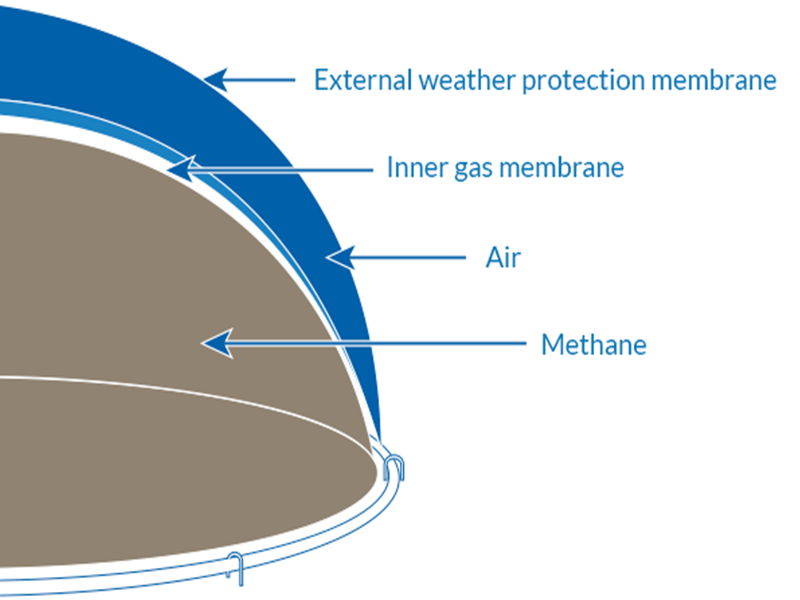

A second stage digester, called a static pillow tank, continues the digestion process of the screened liquor and produces useful biogas, a renewable energy. This liquor, a slow release fertiliser, can be used when diluted as a liquid plant feed and the separated solids can be further composted and used as fertiliser to enhance plant growth.

The PG Digester System Models:

|

Feedstock (example) |

Capacity Tonnes per day |

Estimated Biogas Yield m³/hr |

Estimated Electricity kW |

Potential Heat kW |

|

PG1 |

Garden and Food, including Animal By-Product wastes | 0.8 - 1.2 | 0.2 - 3 | 0.5 - 4 | 4.0 to 10.0* |

PG2 |

Garden and Food, including Animal By-Product wastes | 1.5 to 2.2 | 2.0 to 4.5 | 4.0 to 9.0 | 6.0 to 18.0* |

PG3 |

Slurry (liquid waste) | 7 to 9 | 5 to 8 | 9 to 15 | 20 to 30* |

PG4 |

Slurry (liquid waste) | 10 to 13 | 8 to 11 | 15 to 22 | 30 to 45* |

The PG3 and PG4 units are ideal for dairy cattle bedded on sand, as the sand is displaced and separated by grit traps in the trailer hydrolysis unit.

*Estimated biogas yield is from an additional methane stage digester. PG1 and PG2 gas yields are for typical assorted food wastes, eg. 50m³ per tonne. PG3 and PG4 gas yields are for typical cattle slurry eg. 20m³ per tonne. Gas yields can vary due to type of feedstock. Potential electricity from a typical biogas powered generator. Potential heat from a typical biogas fired boiler.

Examples of PG systems in operation

Our PG systems have proven themselves on various sites including:

- East Devon Council JV Otter Rotters – Treating foodwaste from 500 homes, the biogas was used in a CHP generator to charge the battery collection vehicle. The recovered solids composted and was used in an adjacent commercial nursery.

- H.M Prisons – Seven PG units treating foodwaste. Fertiliser rich compost and biogas used in greenhouses for the production of home grown vegetables and salad crops. The first prison digester system was opened by HRH Princess Anne.

- Orkney Isles – PG unit, a primary pasteuriser for treating fish wastes before adding into an existing AD plant.

- Channel Islands and Co. Waterford - Two PG units treating foodwaste and used on trials for other feedstocks.

- Harper Adams University - PG unit for Horizon 2020 research programme.

Why Choose Our PG System?

J & J Carter are proud to have partnered with Bioplex, to develop a new generation of an anaerobic digester (AD), that will turn waste into an eco-friendly and sustainable energy source. In addition, our PG system users will enjoy additional benefits such as; organic fertiliser generation, low capital installation cost, and odour containment, in addition to being relocatable.

Environmental & Agricultural Solutions

How to Reduce your Farm Waste Pollution

Why Invest in Biogas?

Biogas Storage System at Windover Farm

Home Farm - Anaerobic Digester

FARM250 Anaerobic Digester FAQs

Biogas - the Renewable Solution